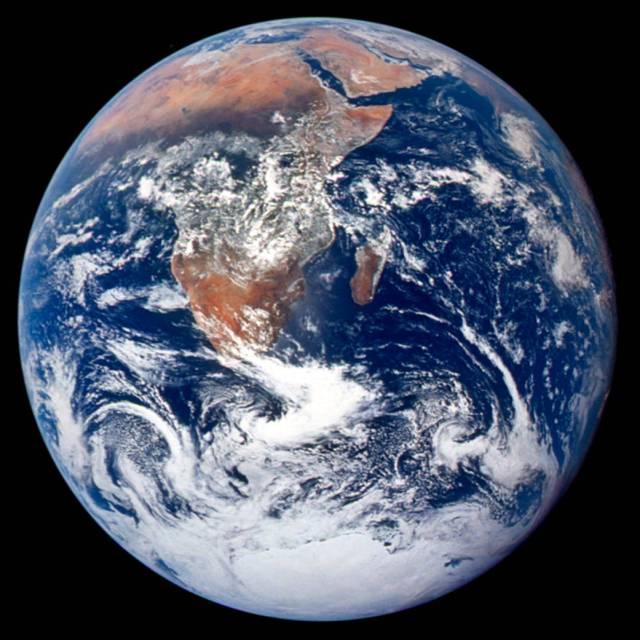

At the heart of future rocket engines lifting off to the Moon or Mars could be a 3D printed combustion chamber. Multiple NASA centers partnered with Virgin Orbit to develop and test a uniquely manufactured rocket part.

Virgin Orbit air launches rockets carrying small satellites to space. The company partnered with NASA experts in combustion and additive manufacturing, or 3D printing, at NASA’s Marshall Space Flight Center in Huntsville, Alabama; Glenn Research Center in Cleveland; and Armstrong Flight Research Center in Edwards, California. Their goal: to create a 3D printed combustion chamber that combines multiple materials and takes advantage of cutting-edge manufacturing processes.

“Traditionally, it takes many months to manufacture, test and deliver a conventional combustion chamber. We can reduce that time considerably,” said NASA senior engineer Paul Gradl, who leads the joint project at Marshall. “Additive manufacturing is primed to augment and enhance traditional processes. It provides new design and performance opportunities and yields a highly durable piece of hardware – and with this partnership, we’re advancing that capability even further.”

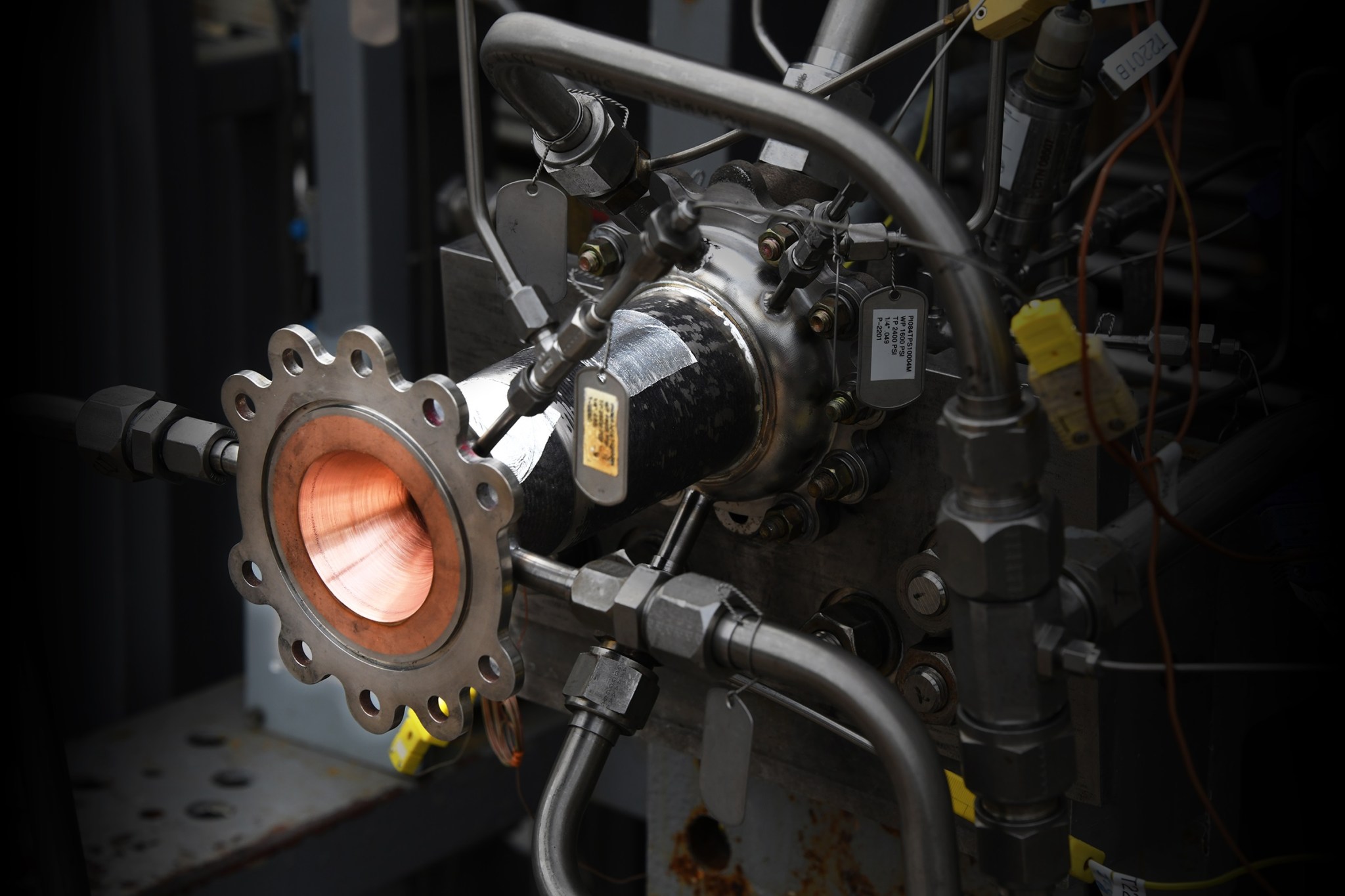

The effort incorporates a proven NASA additive copper alloy, GRCop-84, which was developed at Marshall and Glenn in 2014 to successfully print and test the first full-scale 3D printed copper rocket engine part. To further strengthen this new engine thrust chamber, Virgin Orbit used its own hybrid additive/subtractive machine to apply a second bimetallic super-alloy jacket and precisely machine the part.

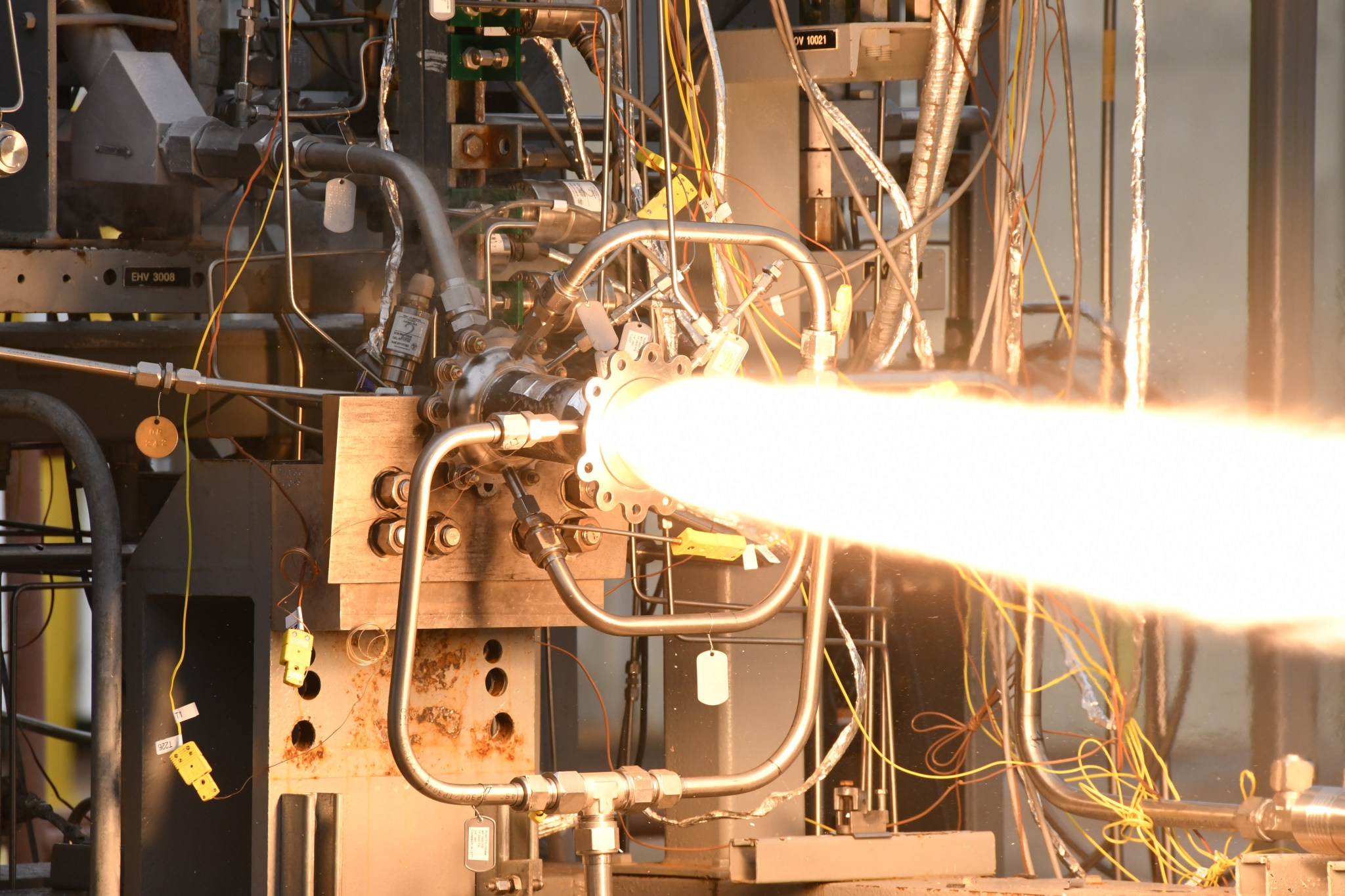

In late 2018 and early 2019, Marshall, in consultation with Glenn and Virgin Orbit engineers, tested the combustion chamber using high-pressure liquid oxygen/kerosene propellants. The test article delivered more than 2,000 pounds of thrust successfully in nearly two-dozen, 60-second test firings.

“The combination of multiple optimized materials and additive manufacturing technologies we’ve employed represents a significant advancement from the compromises typically made in the production of 3D printed rocket engine combustion chambers,” said Kevin Zagorski, Propulsion Advanced Manufacturing manager at Virgin Orbit.

“Information gained from our partnership with NASA will be key in applying these technologies to further improve cost, performance and lead time of Virgin Orbit’s propulsion systems for the LauncherOne vehicle,” he added.

NASA’s goal is to continue working with industry to advance technology and improve access to space by making launch technology safer, faster and more cost effective, said Ed Hamlin, project manager at Armstrong.

“Public-private partnerships like this one are instrumental to maturing critical technology and achieving the nation’s strategic goals in space for decades to come,” Hamlin said.

At Marshall, that means refining 3D printed combustion devices even further by exploring even higher-performing copper alloys. In time, Gradl said, additive manufacturing solutions could support a variety of crewed or robotic deep space exploration missions, including lunar landers and advanced propulsion systems. Earth-based applications also may present themselves.

The collaborative partnership between NASA and Virgin Orbit, created via an Announcement of Collaborative Opportunity by NASA’s Space Technology Mission Directorate, seeks to advance technology across the commercial sector and benefit future NASA missions, reducing launch costs and enabling more robust scientific exploration of the Moon and Mars.

Learn more about NASA’s exploration plans, visit: