If walls could talk, Building 4619 at NASA’s Marshall Space Flight Center in Huntsville, Alabama, would have a lot to say about testing rockets.

The multipurpose, high-bay test facility has been a hotbed for all types of testing, including loads, acoustics, vibration, extreme temperatures, high-and-low pressures, and environments that simulate the cold, black conditions of outer space. More recently, it served as the hub for a series of large-scale “can-crushing” tests to study buckling in structures with the purpose of building lighter, more efficient and affordable launch vehicles.

Today, teams are breathing new life into the 4619 load test annex — part of Marshall’s Structural and Environmental Test Laboratory — for the next era of space exploration with the world’s most powerful rocket, NASA’s Space Launch System. SLS will launch crews of up to four astronauts in the agency’s Orion spacecraft on missions to explore multiple, deep-space destinations, including Mars.

Construction is underway at the facility on steel reaction towers and fixturing that will be used for structural loads testing on the SLS core stage intertank and engine section. The core stage, towering more than 200 feet tall with a diameter of 27.6 feet, has two separate tanks for storing cryogenic liquid hydrogen and liquid oxygen that will feed the vehicle’s RS-25 engines.

The core stage intertank is the connection component between the liquid hydrogen and liquid oxygen tanks, and the attachment point for the rocket’s two, five-segment solid rocket boosters. The engine section structure, also part of the core stage, houses the rocket’s four RS-25 engines.

“It’s exciting to be a part of the future of human spaceflight,” said Tim Flores, integration manager for the SLS Stages Office at Marshall. “Testing this hardware is a major stepping stone before the first flight of SLS.”

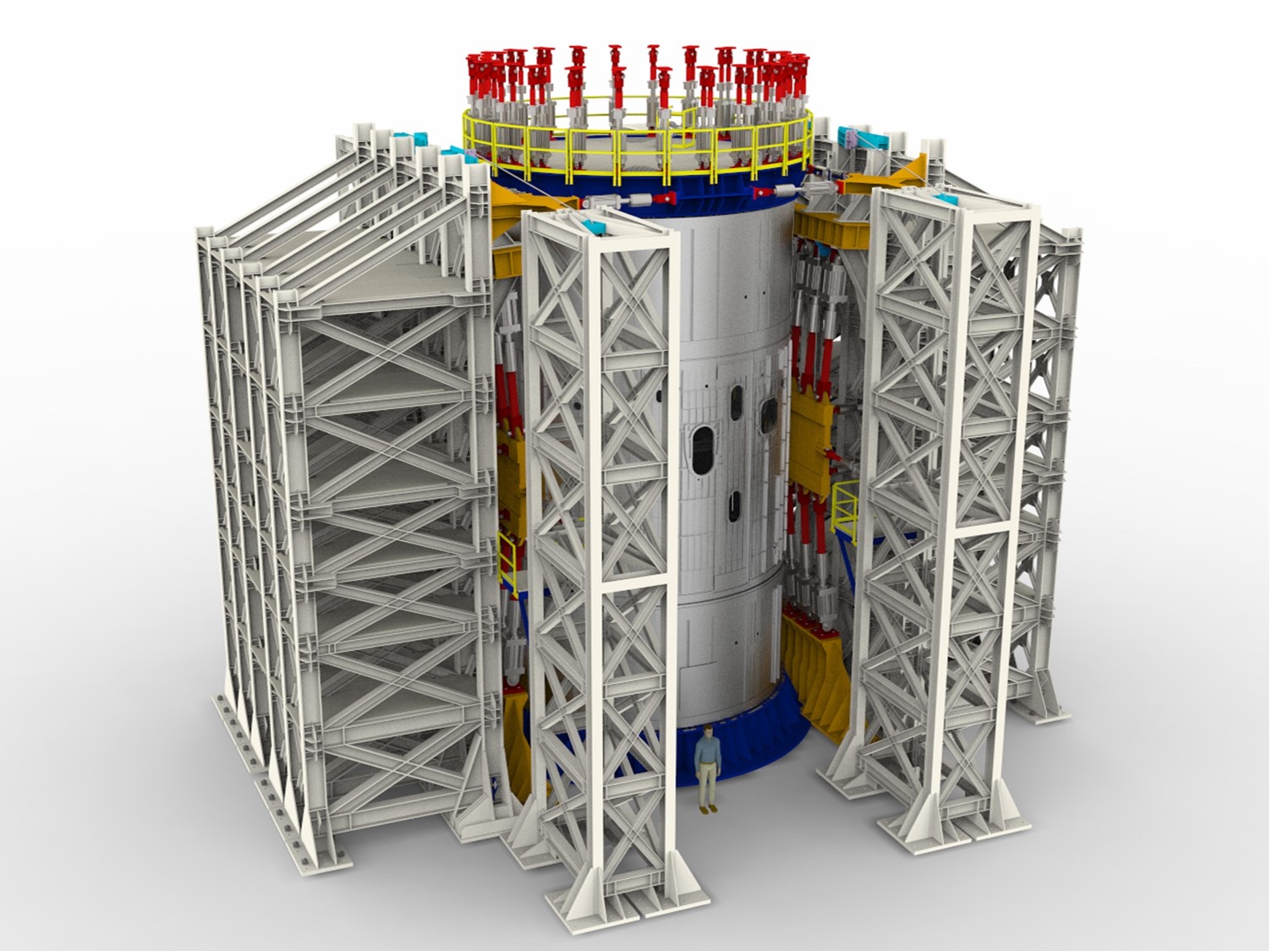

Twelve, 55-foot intertank main tower panels, built and delivered by Weldall Manufacturing Inc. of Waukesha, Wisconsin, have been installed in the 4619 load test annex. One of the next steps will be the delivery and installation of four additional tower structures, which are being manufactured by Steward Machine Co. of Bainbridge, Georgia. In late April, the base frame for the engine section test structure will be delivered from Weldall and installed into another bay of the 4619 load test annex.

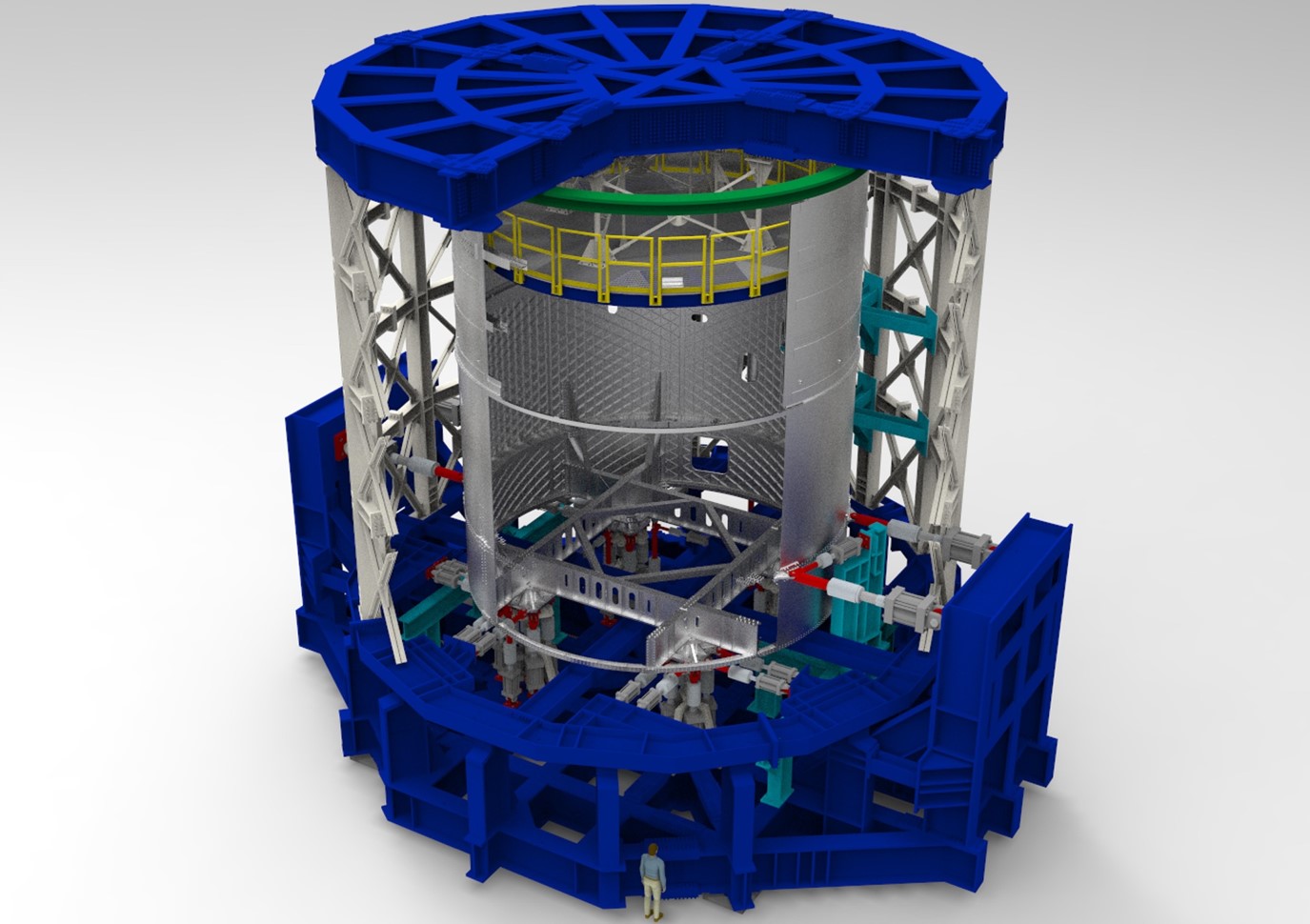

Hydraulic cylinders mounted to the main towers will apply force, or test loads, to the core stage intertank to simulate prelaunch, launch and spaceflight structural load conditions. The 62-foot-tall intertank test structure and 50-foot-tall engine section test structure will use up to 96 hydraulic cylinders on each piece of hardware, with some cylinders weighing more than a car.

The intertank and engine section qualification test articles will be installed in the new structures, and the hydraulic cylinders will be electronically controlled to push, pull, twist and bend the test articles with millions of pounds of force. Engineers will record and analyze approximately 4,000 channels of data for each test. The tests verify the capabilities of the structures, and validate the design and analysis models already in place accurately predict the amount of loads the core stage can withstand during launch and ascent.

“It’s amazing that right outside my office in our laboratory high-bay, we’re constructing the facility, structures, and systems to perform such crucial tests on the SLS intertank and engine section,” said Robert Bobo, the lead for Marshall’s structural testing branch. “Test engineers, designers, analysts and skilled technicians have been planning and preparing for this work for months, and now we’re seeing it actually happen. We’re anxious, and excited, to get our hands on the hardware.”

Both test structures in the load test annex are scheduled to be completed later this year, along with two new test stands that will be used for structural loads testing on the core stage liquid hydrogen and liquid oxygen tanks, plus related hardware. The first test of the series will be on the engine section and is planned to begin in the summer of 2017. All structural qualification test articles for the core stage are currently being built at NASA’s Michoud Assembly Facility in New Orleans and will be shipped on the newly refurbished Pegasus barge for testing at Building 4619 and the two new stands.

“One of the many challenges we face in testing is the logistics of moving hardware,” Flores said. “We may have the facilities and test articles ready, but it takes a lot of planning to ensure we have the right equipment, cranes, and ground support equipment in place to get the hardware to the appropriate test areas.

“The test articles that will form the SLS are so heavy that some roads are not strong enough to bear the weight of the hardware,” Flores continued. “In most cases, we are dealing with such large hardware we have to make our own equipment to transport it on those roads. And in some cases, we rebuild the roads. Our logistics team is working every scenario right now to ensure we can transport the hardware in the most efficient manner.”

A 213-foot, 230,000-pound mockup of the core stage also is in production and will be used to demonstrate core stage operations, transport and routes for testing, assembly and launch. The Boeing Co. of Chicago is prime contractor for the core stage, including avionics.

The SLS Block I configuration will have a minimum 70-metric-ton (77-ton) lift capability and be powered by twin boosters and four RS-25 engines. The next planned upgrade of SLS, Block 1B, would use a more powerful exploration upper stage for more ambitious missions with a 105-metric-ton (115-ton) lift capacity. Block 2 will add a pair of advanced solid or liquid propellant boosters to provide a 130-metric-ton (143-ton) lift capacity. In each configuration, SLS will continue to use the same core stage and four RS-25 engines.

For more information on SLS, visit:

Tracy McMahan

Marshall Space Flight Center, Huntsville, Alabama

256-544-0034

tracy.mcmahan@nasa.gov

Kim Henry

Marshall Space Flight Center, Huntsville, Alabama

256-544-0034

kimberly.m.henry@nasa.gov