Our job at NASA Glenn is to advance technologies that have the potential to change the way we explore space and also change our lives on Earth. Teams of scientists have partnered with industry to produce these five recent innovations.

Detecting Smoke and Fire

When detecting hazards in the air, a fast and informed response can save lives. Glenn scientists had this in mind when they developed MPASS (Multi-Parameter Aerosol Scattering Sensor) for determining air quality on the International Space Station. They found many other uses for this cutting-edge optical sensor, which identifies particles suspended in the air and their properties.

Because MPASS sensors are light and compact, they are being considered for respiratory health monitoring applications for first responders, miners, disaster relief services and other environmental workers.

Predicting Aircraft Icing Dangers

Conditions can quickly become dangerous when aircraft encounter icing conditions at high altitude. A new tool to help understand icing risk has been developed at NASA Glenn.

LEWICE3D is a software program that computes parameters associated with icing risk by integrating state-of-the-art, fluid flow solutions for Computational Fluid Design software.

Its three-dimensional modeling capability and validation by an extensive database of icing profiles make LEWICE3D the most accurate technology available for the analysis of aircraft susceptibility to ice accretion; ice protection system design; the design of aircraft, rotorcraft, unmanned aerial vehicles, jet engines, probes, and detectors; and aircraft certification.

LEWICE3D may be downloaded with a software usage agreement at no charge from the 2017/2018 NASA software catalog.

Metals with Memory

Shape memory alloys (SMAs) are metal alloys with memory. The groundbreaking materials can be stretched and deformed at low temperature or under force and recover their original shape upon heating or applied load.

The applications are enormous. Glenn innovators have developed a groundbreaking method for using SMAs to split apart rock formations without explosives, hydraulics, or any demolition damage to the surrounding environment. They have also developed SMA tires, a lighter, more durable option for rovers which explore other planets. And they are testing SMA components for use on aircraft wings that fold while in flight.

Next-generation SMA technologies could revolutionize a broad range of industries as varied as oil drilling, hydraulic fracturing, mining, civil engineering, adaptive structures, automotive, aerospace, medical devices, actuators, and search-and-rescue operations.

Sandwiched Solar Cells

As solar power becomes widely adopted, NASA Glenn innovators are working to make it more efficient. Engineer Geoffrey Landis has designed a high-efficiency, multi-junction solar cell that uses a thin interlayer of selenium as the bonding material between wafers.

Selenium’s transparency enables light to pass through the top cell through to the bottom silicon-based cell substrate. Since selenium is also a semiconductor, the efficiency of the cell is improved significantly.

This cell, with selenium sandwiched in between, provides a more robust design for space and a more efficient solar cell for commercial applications, including space-based power systems, solar aircraft, drones, electric vehicle charging stations, auxiliary power units, power plants, and solar roof tiles.

Additional advantages of this solar cell include its ease of manufacture and lower-cost.

Extreme Electronics

When Venus landers reach the surface of the planet, they don’t last long. At nearly 860 degrees Fahrenheit, the electronics might only function for a few hours due to the extreme conditions.

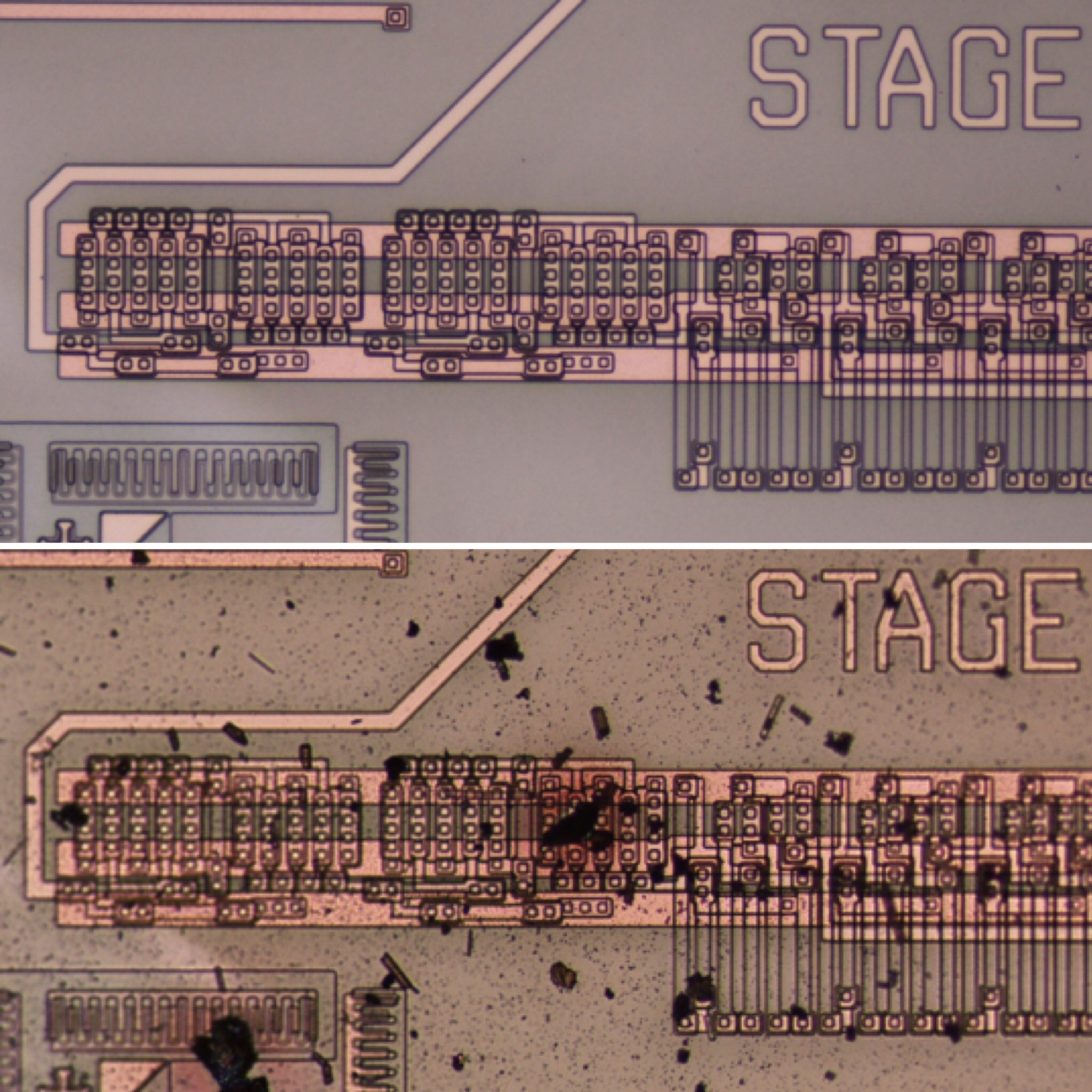

Scientists at NASA Glenn recently completed a technology demonstration that could allow new scientific missions to last much longer. The team developed extremely durable silicon carbide semiconductor integrated circuits and tested them in our extreme environments rig.

The circuits withstood the Venus surface temperature and atmospheric conditions for over 1,400 hours – operating more than 700 times longer than previously demonstrated Venus mission electronics.

“We demonstrated vastly longer electrical operation with chips directly exposed — no cooling and no protective chip packaging — to a high-fidelity physical and chemical reproduction of Venus’ surface atmosphere,” says Engineer Phil Neudeck. “And both integrated circuits still worked after the end of the test.”

These extreme electronics could have a significant impact for a range of Earth applications, including use within hot regions of fuel-efficient aircraft engines.

These are just a few of the innovative technologies being advanced by innovators at NASA Glenn as we shape the world of tomorrow to enable further exploration of the universe and revolutionize air travel.

For information on additional technologies please visit: https://technology.grc.nasa.gov/