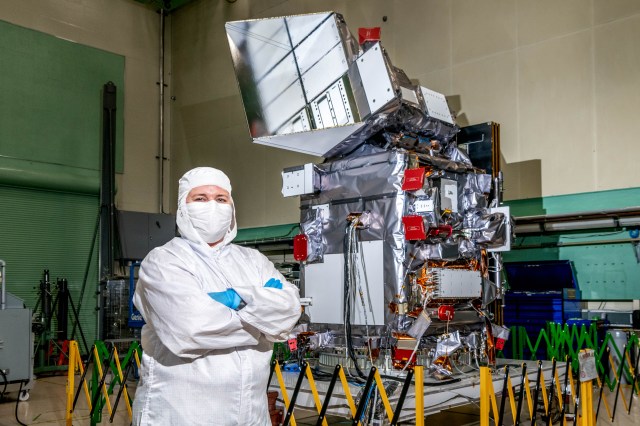

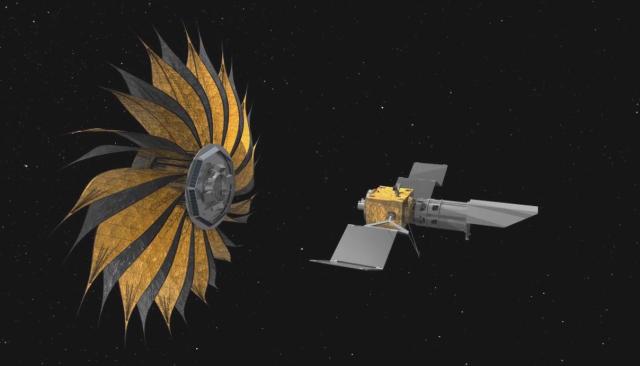

The Orion spacecraft Structural Test Article (STA) completed its cross-country road trip Tuesday to NASA’s Langley Research Center in Hampton, Virginia in preparation for a series of water impact tests at the center’s Landing and Impact Research Facility, or gantry.

The tests, scheduled for early 2021, will look similar to previous tests. This time, however, the crew module is more flight-like in its configuration with several structural updates and modifications based on data from wind tunnel tests and Exploration Flight Test-1.

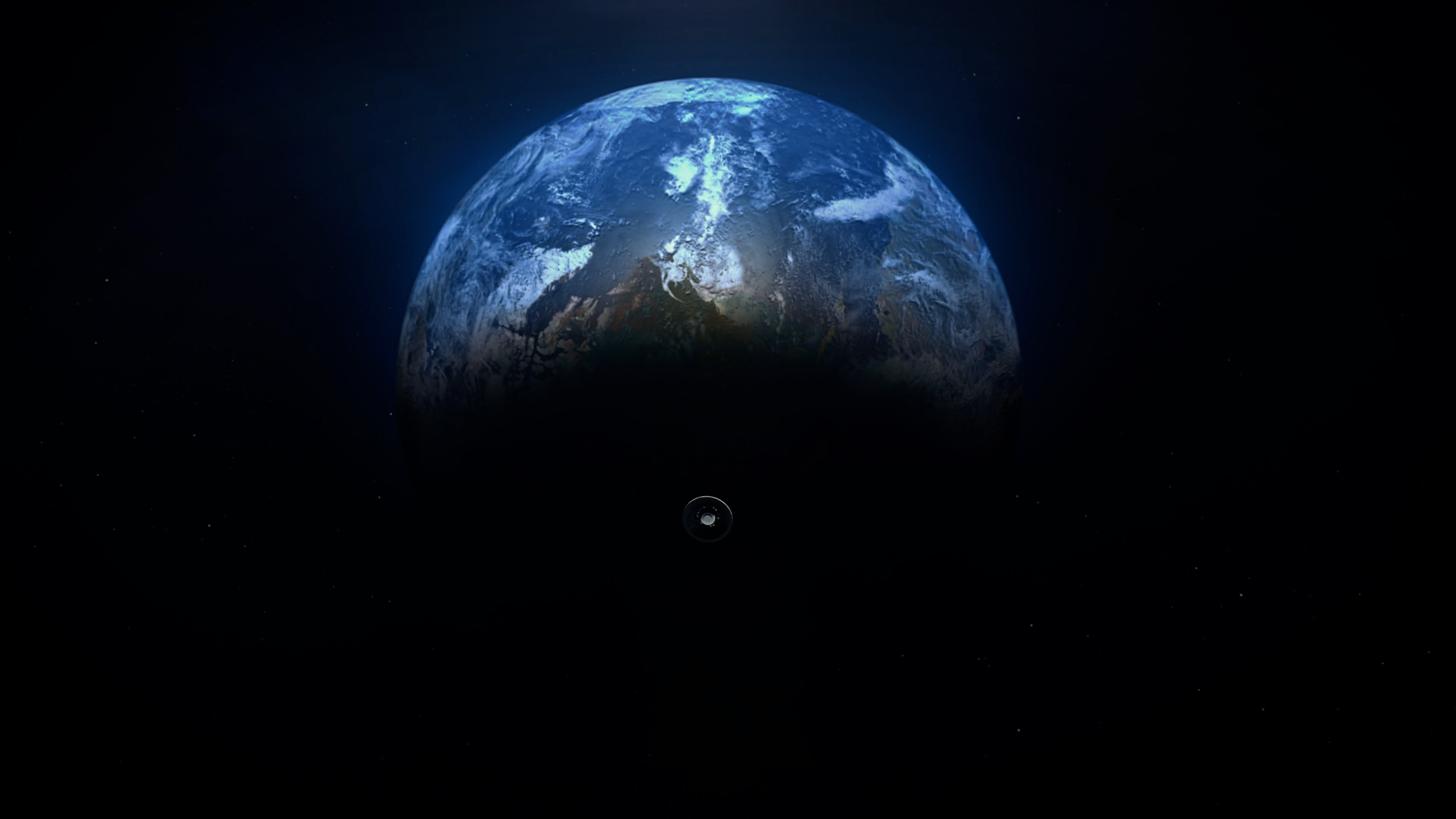

Data from the upcoming drop tests will be used for final computer modeling for loads and structures prior to the Artemis II flight test, NASA’s first mission with crew. Artemis II will carry astronauts around the Moon and back, and will pave the way to land the first woman and next man on the lunar surface during Artemis III.

“This is less about trying to reduce model uncertainty and more about loading up to design limits, bringing the model higher in elevation and higher in load, not testing to requirements, but testing to extremes,” said Chris Tarkenton, technical lead.

Refining for Flight-like Testing

“The engineering design process is iterative so as you learn more about how the structure behaves then you, as the designer, make updates to address what you learn from tests,” Tarkenton said. “And design doesn’t just mean overall shape, it’s how all of the components will interact and how it will be manufactured.”

In 2011, engineers started testing with a rough model of Orion, the boilerplate test article, in a series of drops at Langley’s Landing and Impact Research Facility Hydro Impact Basin. Engineers learned how different test conditions compared to computer simulations and made adjustments to Orion’s design. Then in 2016, the more refined ground test article was tested to better understand the forces the crew module would experience during a water landing. Again, small modifications were made to the design based on test results. Now, based on the final design for the configuration that will fly on Artemis II, the structural test article will be put to the test.

“As the crew module design has been matured the test articles at each stage have become more refined and flight-like. This model of the Orion crew module includes flight designs of the pressure vessel barrel, backshell panels, and heat shield as well as higher fidelity secondary structures and other components,” said Bryan Russ, project manager.

Built at lead contractor Lockheed Martin’s facility in Colorado, this structure has been changed slightly based on data from previous testing and is more flight-like than the ground test article. The test engineers will be looking for different data this time around as well.

“During the drops with the ground test article, we did a number of different test configurations to reduce the model uncertainty. That equates to weight savings and structure savings,” Tarkenton said. “Now we’re going to load up the structure near its ultimate values – adding energy, measure strains and stresses to make sure structure matches the computer model.”

During the upcoming test series, the team will simulate a few landing scenarios as close to real-world conditions as possible. After the tests, data will be used to validate the computer models before flying with crew.

“Thousands of possibilities will be whittled down to some critical cases, we’ll examine the data and make sure the models correlate to test and adjust models as needed to gain confidence,” Russ said. “It helps us to know that the models are reliable and representative of what will be experienced during flight scenarios.”

No Small Parts in Big Test

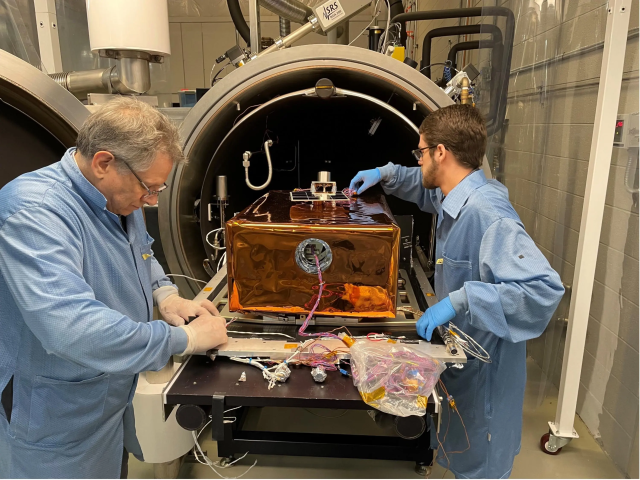

After unwrapping the crew module, engineers will spend the next few months installing data acquisition systems and cable harnessing, as well as hydrogen monitoring sensors.

More than 500 sensors, including strain gauges and accelerometers are already installed on the inside, backshell and heat shield.

Engineers and technicians will also install waterproofing closeout panels, 3D printed at Langley, to prevent water intrusion. During testing, weight checks between drops and visual inspections will ensure no water is getting in areas it shouldn’t.

“We have a lot of support hardware being manufactured and modified over the months leading up to the test, and there will be some facility preparation as well,” Russ said. “On top of all the project related work, we are going through the extensive processes to safely return the team to work on site during the COVID-19 pandemic.”

“Coordination will be key. We’ll have multiple activities happening simultaneously while trying to follow all return to on-site work Covid-19 protocols,” added Kenny Walters, assistant branch head and test director.

The water impact tests of the Orion structural test article are part of the formal qualification test program to fulfill structural design and requirement verification before Artemis II.

Under the Artemis program, NASA is working to land the first woman and next man on the lunar surface in 2024, and establishing a sustained presence by the end of the decade. The agency will leverage its Artemis experience and technologies to prepare for humanity’s next giant leap – sending astronauts to Mars.