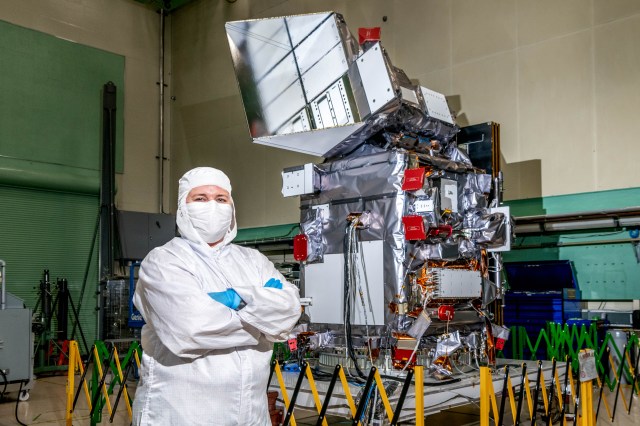

Michelle Tillotson, a Wilmington, Delaware, native and stress analyst at NASA’s Marshall Space Flight Center in Huntsville, Alabama, is part of a team working to reduce costs and risks for NASA’s next-generation rocket. And that’s not just any rocket – it will be the world’s most powerful launch vehicle. It’s called the Space Launch System (SLS).

When completed, SLS will be capable of taking a crew and cargo on deep space missions, including to an asteroid and eventually to Mars.

Tillotson is the manufacturing lead at the Marshall Center for the NASA Shell Buckling Knockdown Factor Program. In rocket science and engineering, every pound counts, and it costs to lift every pound to orbit. Rocket tanks are one of the heaviest parts of the rocket. If engineers can make tanks stronger and lighter, rockets can carry heavier payloads to space. That’s the goal of the Shell Buckling and Knockdown Factor Project, led by the NASA Engineering and Safety Center (NESC) in collaboration with Marshall and teams at NASA’s Langley Research Center in Hampton, Virginia.

“The test articles are critical to the validation of new design methods, and the benefits from this research will touch all aspects of the SLS Program by initiating reductions in the SLS core stage design cycle time, material and fabrication cost, and structural mass,” said Tillotson.

The SLS core stage will stand at more than 200 feet tall with a diameter of 27.6 feet. It will store cryogenic liquid hydrogen and liquid oxygen that will feed the vehicle’s RS-25 engines.

Tillotson earned a bachelor’s degree in civil engineering in 2010 and a master’s degree in structural engineering in 2011 from Lehigh University in Bethlehem, Pennsylvania. After working in the private industry in Allentown, Pennsylvania, for a year, she joined NASA in 2013 in the Marshall Center’s Spacecraft & Vehicle Systems Department, part of the Engineering Directorate.

“I love working on this project for SLS because I am witnessing history in the making,” Tillotson said. “We are taking advantage of the newer, more accurate computational methods to change the way we’ve been designing buckling critical components for the last 60 years. It’s very exciting.”

Tillotson will be sharing her experiences working on the SLS project at the Lehigh Valley Airshow in Allentown. She will be speaking at 11 a.m. Aug. 23-24 at the NASA booth at the airshow.

The first flight test of the SLS in 2017 will feature a configuration for a 70-metric-ton (77-ton) lift capacity and carry an uncrewed Orion spacecraft beyond low-Earth orbit to test the performance of the integrated system. As the SLS evolves, it will provide an unprecedented lift capability of 130-metric-tons (143-tons) to enable missions even farther into our solar system.

For more information on SLS, visit:

https://www.nasa.gov/exploration/systems/sls/

Shannon Ridinger

Marshall Space Flight Center, Huntsville, Ala.

256-544-0034

shannon.j.ridinger@nasa.gov