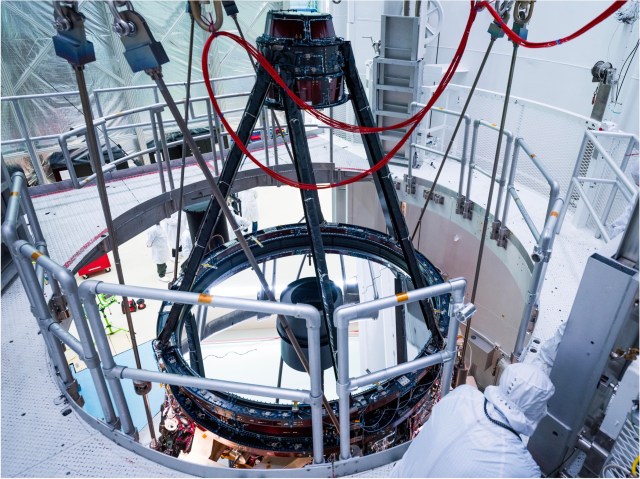

The high bay designed to process, test and complete a multitude of modules for the International Space Station will be able to house a robust assortment of space-bound hardware after continued modifications to the Space Station Processing Facility free up zones tailored to a variety of needs by commercial space companies and other NASA programs.

For instance, even moving the operations desk about 40 feet so it doesn’t restrict a large doorway was a small amount of work that made the high bay more accessible from nearby laboratories, said Bill Dowdell, International Space Station technical director.

“I think it’s important for people to come in here and see that we are organizing and getting ready for that eventuality of commercial entities operating in this building along with NASA programs,” Dowdell said. “It’s in keeping with what we’ve done before with industrial operations zones. This enables us to give people a footprint of their own to work in.”

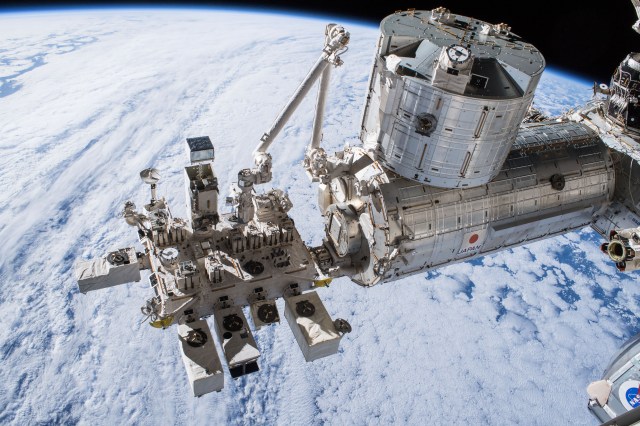

Although the space station has been complete for more than five years, the processing hall has been used to prep numerous other missions including Orbital ATK Cygnus spacecraft for two cargo resupply missions. Orbital ATK, with help from Jacobs’ engineers and specialists under the Test and Operations Contract, or TOSC, will use the high bay again for a third Cygnus spacecraft that will fly on the company’s seventh contracted mission to the space station in spring 2017.

The area is equipped with a wide range of specialized equipment including high-pressure systems to fill tanks that provide breathing air to the crew members on the space station, also supported by Jacobs’ technicians. The third International Docking Adapter, which will launch on a future SpaceX cargo resupply mission destined for the station, is being assembled in the bay just as the previous two were.

More than the allocation of room in the high bay for work, former astronaut Bob Cabana, Kennedy’s director, said the main attraction is the center’s team of engineers and specialists that help companies work through processing.

Relating the opportunity to his own experience as an astronaut reviewing processing of the Unity node of the station, Cabana said Kennedy’s work force showed repeatedly they could accomplish significant testing and processing that led to a near-flawless construction of the space station in orbit.

“This is the premiere place to process hardware and this is our stepping stone to the future and it’s right here,” Cabana said.

The modifications to the Space Station Processing Facility are the latest in a continuing line of improvements across the Florida spaceport. Rather than shape its facilities for a single program and spacecraft, Kennedy is becoming home to multiple programs, spacecraft and rockets. For example, former space shuttle hangars are being used for a new generation of human-rated spacecraft, launch pads have been refit to support large new rockets and the Vehicle Assembly Building has been modernized.