How easy would it be to take the engine out of your current car and stick it into a different car? If you’re a mechanic, you know it is entirely possible but would take some care.

That’s what NASA’s doing now to get the RS-25 rocket engine that successfully powered the space shuttle fleet for 30 years ready to fly on NASA’s next great rocket, the Space Launch System (SLS).

NASA is designing SLS, which will be capable of exploring deep space destinations like an asteroid and eventually Mars, with affordability in mind, and using a combination of heritage hardware and modern manufacturing practices.

The agency’s new rocket will build on the success of the RS-25 space shuttle main engine, the shuttle’s solid rocket booster and the 27.5-foot-diameter external tank manufacturing infrastructure. The result will be the most powerful launch vehicle in the world, with more than twice the payload mass of the shuttle.

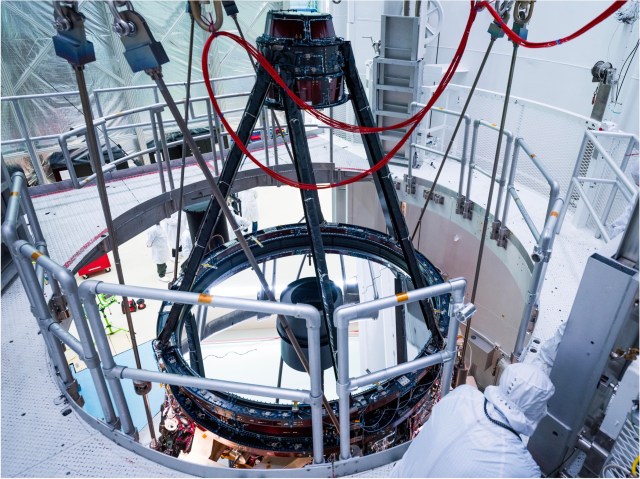

The SLS core stage is designed around four RS-25s. NASA has 16 flight engines currently in its fleet, as well as two of development engines for ground testing. Engineers have performed extensive analysis to understand how the engines will work for SLS, but will continue to study the integrated design with detailed analysis and, ultimately, by firing the engine on its test stand at NASA’s Stennis Space Center near Bay St. Louis, Mississippi.

“The RS-25 is the most efficient engine of its type in the world,” said Steve Wofford, manager of the SLS Liquid Engines Office at NASA’s Marshall Space Flight Center, in Huntsville, Alabama, where the SLS Program is managed. “It’s got a remarkable history of success and a great experience base that make it a great choice for NASA’s next era of exploration.”

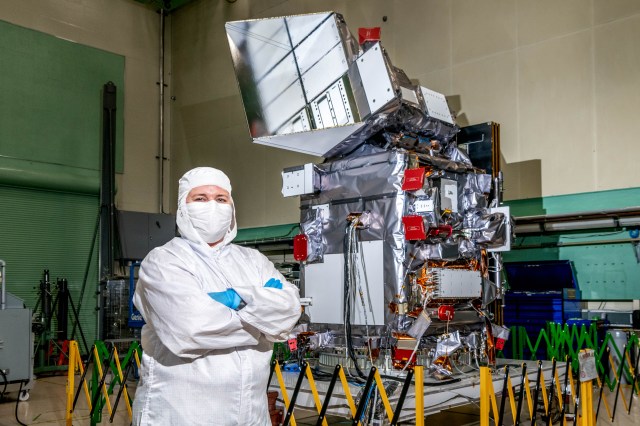

Under an existing contract with Aerojet Rocketdyne, prime contractor for the RS-25, engineers at Stennis are preparing for engine testing to begin the process of adapting the engine to meet SLS performance requirements and environments from the launch pad to space.

On the shuttle, the RS-25 routinely operated at 491,000 pounds of thrust. On SLS, it will operate at 512,000 pounds of thrust for the first four flights. Before launch, the four engines in the SLS core stage will encounter colder liquid oxygen propellant temperatures and a colder engine compartment in the SLS core stage.

Beginning at engine and booster ignition, the engines will encounter higher propellant inlet pressure and greater exhaust nozzle heating due to differences in the SLS design. The higher thrust and greater cooling, heating and pressure will be part of the upcoming test series and later core stage testing. The upcoming tests will also include the new engine controller design that replaces the RS-25’s original three-decade-old engine computer.

NASA plans to restart RS-25 production to provide engines for future flights by working with Aerojet Rocketdyne to further adapt and modify the engine design to be more affordable, while increasing the planned thrust to 521,700 pounds.

“We had identified significant cost and time saving ideas for the RS-25 before the shuttle program ended,” Wofford said. “We see many opportunities for process and manufacturing savings with the change to an expendable engine and the maturation of technologies, such as 3D printing and structured light scanning.”

Initial production will be for six new engines and more beyond that once NASA gains experience with the design and manufacturing changes. With that, the RS-25 is expected to be exploring space for many more decades and building on its space shuttle legacy.

For more information on SLS, visit: